Definition and role of the maintenance order in the success of maintenance operations.

A service order is a fundamental document in maintenance management, serving as a bridge between service requests and actions carried out in the field. This often underestimated document plays a key role in the organization and documentation of maintenance tasks, whether preventive, corrective or improvement.

A well-designed work order enables maintenance requests and actions to be formalized, detailing the nature of the problem, the actions to be taken, the parts required, and the specific instructions for each intervention. The relevance of this document lies in its ability to provide a written record of operations, essential not only for day-to-day management but also for future audits, failure analyses, and validation of maintenance practices in line with current standards.

A well-designed work order enables maintenance requests and actions to be formalized, detailing the nature of the problem, the actions to be taken, the parts required, and the specific instructions for each intervention. The relevance of this document lies in its ability to provide a written record of operations, essential not only for day-to-day management but also for future audits, failure analyses, and validation of maintenance practices in line with current standards.

In addition to its operational role, the work order serves as a legal basis in the event of disputes or claims. It proves that the work has been carried out in accordance with the initial requests, thus making it possible to verify that interventions have been carried out correctly and on time. That’s why it’s vital to understand that this document, far from being a mere administrative formality, is an essential tool for ensuring the quality and traceability of maintenance work.

The creation and use of a service order reflects a company’s professionalism and commitment to its maintenance and customer service standards. Its importance increases in the industrial sector, where maintenance is regularly required, and where the consequences of a failure can be significant, both in terms of cost and safety.

From request to work order

The purpose of a service request

A service request is a formal request, either in writing or via Computerized Maintenance Management System (CMMS) software, which compiles all the information needed for the maintenance department to plan and intervene effectively. This request is the first step in the maintenance process, designed to signal a need for intervention on a specific piece of equipment.

The work order: a formal authorization

Following an intervention request, an intervention order is generated once the intervention has been approved. This official document authorizes technicians to carry out the necessary work. It specifies the nature of the problem, the estimated cost, the expected repair time and the technician assigned. It is this document that starts the process of managing the maintenance task.

What elements should never be missing from a service order?

A service order is more than just an operational document. Its quality is based on precise elements that guarantee smooth execution and optimal traceability of interventions. Every detail helps to structure the process and avoid inaccuracies that could lead to delays or misunderstandings.

- Unique identifier

Each work order must have a unique identification number. This enables precise tracking in management systems and avoids confusion between several similar interventions, especially in environments where operations are frequent.

- Applicant and site information

The identity of the caller, together with details of the site concerned, are essential. This information enables the technician to quickly locate the intervention and, if necessary, contact the manager or team on site for further details.

- Date and time

Date and time are essential, not only to organize schedules, but also to ensure that operations are tracked chronologically. It also enables us to assess the responsiveness of our teams to requests for assistance.

- Precise task description

An intervention order must clearly specify the nature of the problem or task to be carried out. Whether it involves preventive, corrective or improvement maintenance, this description helps the technician to prepare ahead of time and anticipate the need for equipment or tools.

- Resources required

What spare parts, specific tools or materials are required for this operation? This information helps to avoid interruptions caused by a lack of resources on site.

- Estimated intervention time

Estimating the time needed to carry out the task is a key indicator for efficient planning of operations and minimizing the impact on other activities.

- Specific instructions

For certain complex or sensitive operations, it is imperative to include specific instructions, such as safety precautions to be taken or steps to be followed.

- Observations or comments

A section dedicated to remarks or particularities linked to the intervention (such as difficult access or time constraints) enriches the voucher with useful information that facilitates its execution.

- Signature for validation

Once the work order has been completed, it must be signed by the technician and, if possible, by the on-site manager. This step formalizes the process and ensures mutual validation of the information recorded.

By bringing these elements together, the work order becomes a structured tool that promotes smooth execution and accurate documentation. Omitting any of these aspects, however minor, can lead to costly complications, both in terms of time and resources.

How to write a clear and effective work order?

Writing a clear, well-structured work order is essential for smooth maintenance operations and customer satisfaction. Here are a few tips to optimize the clarity and effectiveness of your work orders.

- Use simple, precise language

Avoid excessive technical jargon that could lead to confusion. Use terms that are clear and understandable to all stakeholders, including customers. Transparent communication facilitates understanding and reduces the risk of errors.

- Structure the document logically

Organize the service order into distinct sections, such as customer information, service description, resources required and observations. This structure makes for quick reading and easy reference to the various parts of the document.

- Specify the details of the intervention

Accurately describe the nature of the intervention, the steps to be followed, the tools required and the precautions to be taken. The more detailed the instructions, the more efficiently the technician will be able to perform the task.

- Incorporate visual elements

Where appropriate, add diagrams, photos or charts to illustrate complex points. Visual elements can clarify instructions and serve as a quick reference in the field.

- Ensure consistency and uniformity

Use standardized templates for your work orders to maintain consistency in presentation and content. This consistency facilitates technician training and ensures consistent documentation quality.

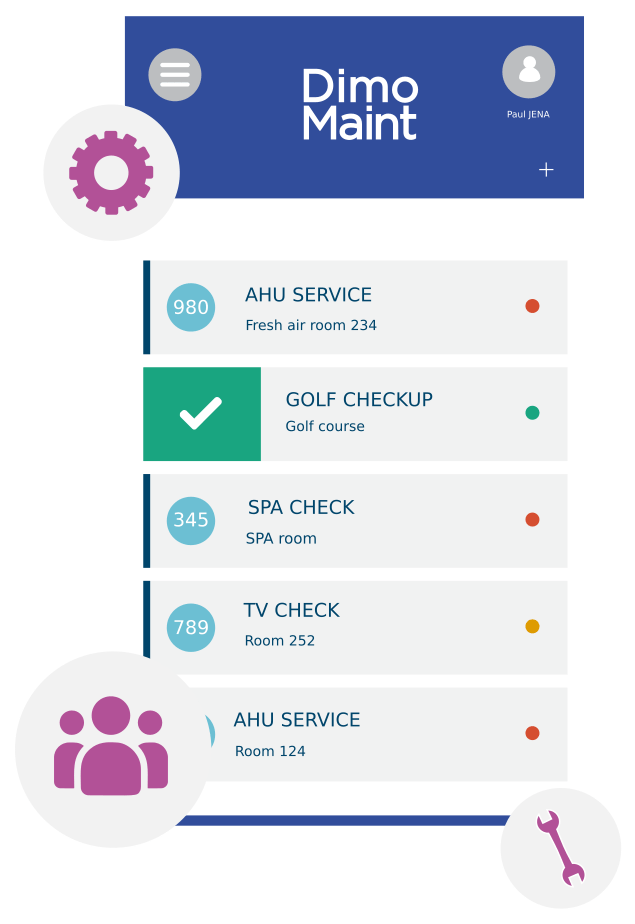

- Make the most of CMMS tools

Maintenance software offers functions for efficiently creating, managing and archiving work orders. They enable you to centralize information, automate certain tasks and facilitate the tracking of interventions.

- Train technicians to write reports

Make sure that your technicians are trained to write clear and complete work orders. Regular training can improve the quality of documents and, consequently, the efficiency of interventions.

By applying these practices, you’ll improve the quality of your work orders, resulting in better organization of maintenance operations and greater customer satisfaction.

What are the advantages of digitizing your work orders?

The digital transformation of work orders offers significant benefits for maintenance managers. By adopting digital solutions, companies can optimize their processes, improve customer satisfaction and boost their competitiveness.

CMMS software is revolutionizing the way requests and work orders are managed. They enable real-time tracking, facilitate the recording of information and help to plan interventions more efficiently, while improving safety and reducing costs.

Greater operational efficiency

Digitization enables optimized task management, reducing the time and resources required for each intervention. Technicians can instantly access the information they need via mobile devices, facilitating the planning and execution of interventions. What’s more, process automation reduces the risk of human error and improves the accuracy of the data collected.

Improved traceability and transparency

Digital work orders offer complete traceability of operations. Every step, from the initial request to the end of the intervention, is recorded and accessible in real time. This transparency facilitates audits and performance analyses, and ensures compliance with current standards.

Reduced costs and lead times

By eliminating paper-based processes, companies reduce the costs associated with printing, storing and managing physical documents. What’s more, the rapid transmission of digital information reduces response times, boosting customer satisfaction and team productivity.

Improved communication and collaboration

Digital solutions promote better communication between maintenance teams, customers and other stakeholders. Information is shared in real time, facilitating the coordination of interventions and reducing the risk of misunderstandings or duplication.

Greater flexibility and adaptability

Digitized work orders can be easily modified, updated or customized according to the specific needs of each intervention. This flexibility enables companies to adapt quickly to changes and continually improve their maintenance processes.

To find out more about how our solution can simplify and optimize the management of your maintenance operations, contact us today.